FlowTrue

For lip seals, packing glands & mechanical face seals

Shop NowDownloads: Installation Instructions

Product Specifications: View technical specifications

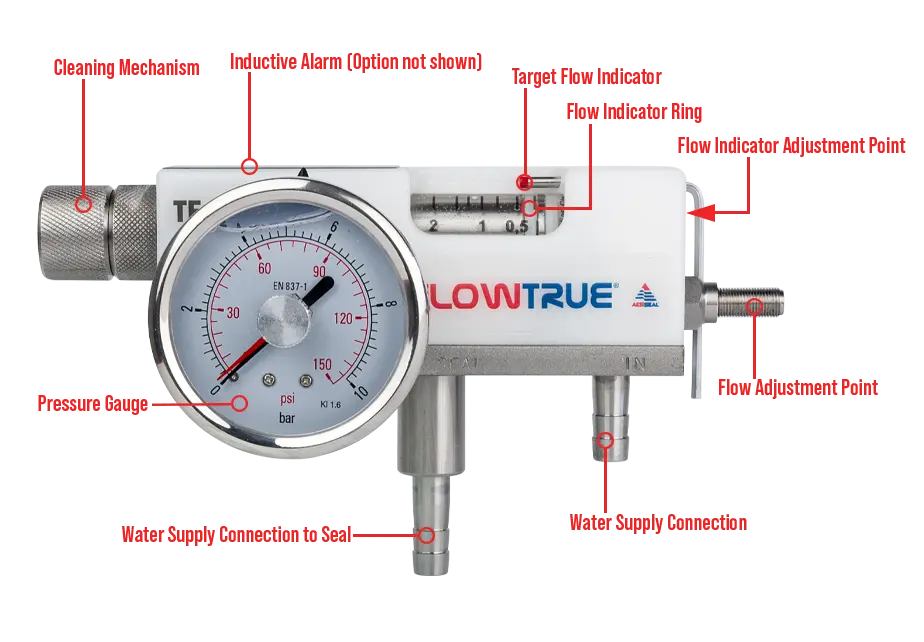

The fully patented FLOWTRUE® is a robust and adjustable flow meter that controls the amount of water flowing to the mechanical seal for cooling purposes.

The unique and advanced FLOWTRUE® design means that of all the flow meters available it is the least likely to clog. This is due to large internal clearances within the design. Three models are available which enables the product to be used on packing applications single seals and double mechanical seals. Additional instrumentation such as flow alarms can be added to introduce even greater control over the sealing environment.

How Does It Work?

1

Turn the flow adjustment point closed.

2

Then set the red target flow indicator to the desired flow rate.

3

Switch on the water supply connection.

4

Open the flow adjustment point until the white left hand ring is in line with the red target flow indicator.

Technical Specifications

| Construction: | Features a main body that is made out of polyacetal, with an 316L stainless steel base and fittings. |

|---|---|

| Maximum Temperature: | 176°F (80°C) |

| Flow Rate (Adjustable): | 0.25 - 2.0 Gallons per min. (1.0 - 8.0 Liters per min.) |

| Pressure (Adjustable): | 0 - 360 PSI (0 - 25 BAR) |

| Fitting Size: | 3/8" |

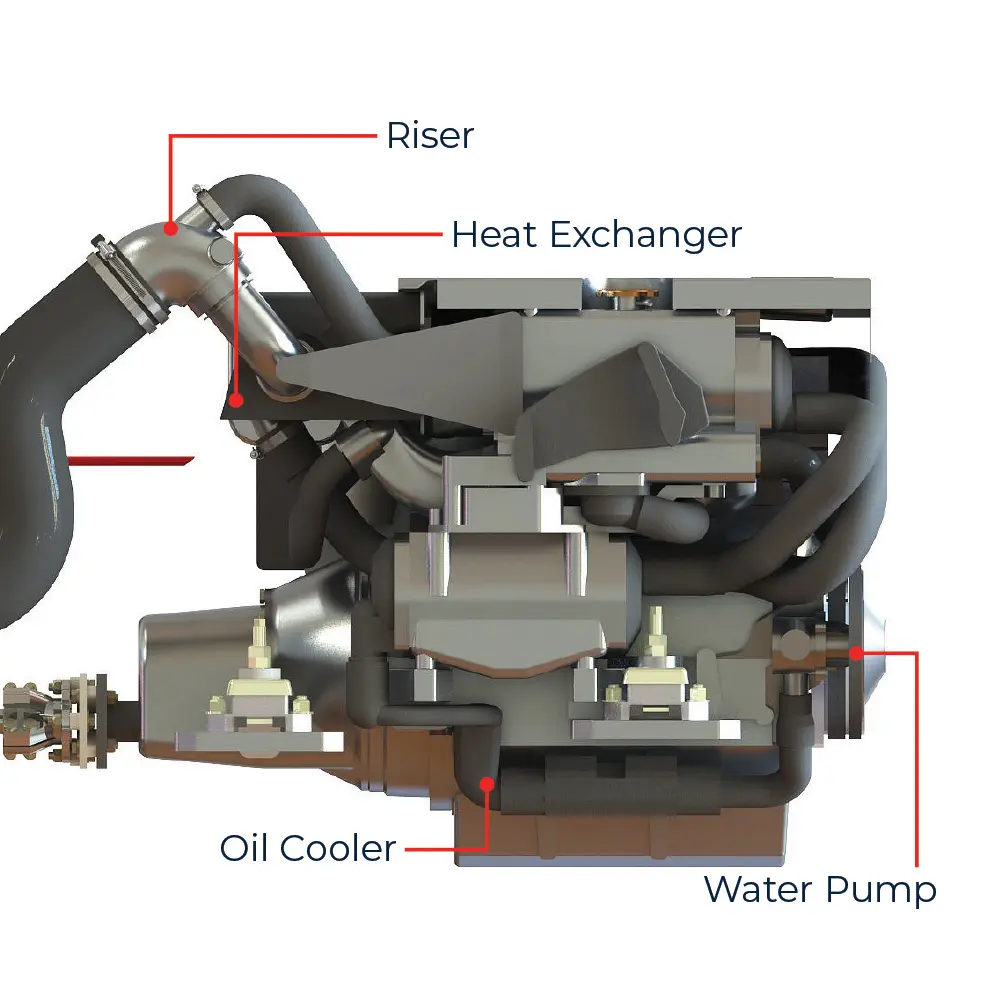

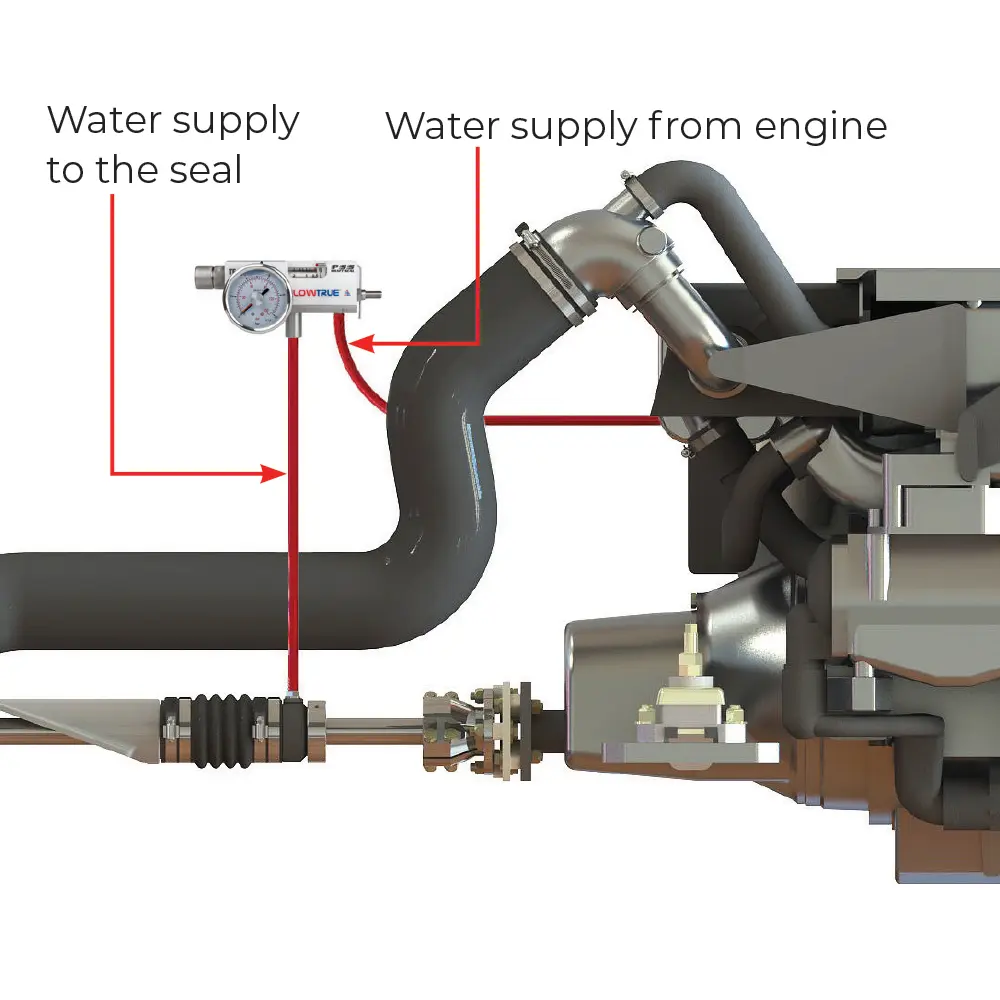

Water Pickup Locations & Installation Example

Water Pickup Locations

Installation Example

Tips

Here are some helpful tips to make sure you get the most out of your PSS Shaft Seal.

For more helpful tips, please visit our FAQ page.

PSS Maintenance Kit

To ensure longevity and proper function of the PSS Shaft Seal, PSS Seal provides a PSS Maintenance Kit to follow the PSS Seal's recommended maintenance schedule. As with any rubber / silicone hose below waterline, the PSS bellows must be inspected on a regular basis for any sign of wear, aging or chemical deterioration. PSS Seal recommends that the bellows be replaced once every 6 years. During the bellows replacement it is also recommended that the o-rings & set screws in the stainless steel rotor are replaced, as well as the hose clamps. PSS Seal includes all of the necessary replacement parts in the PSS Maintenance Kit.

More Info

Set Screws

Please be sure never to use the same set screw on the shaft twice. There are two set screws in each of the two holes in the stainless steel rotor. One is tightened onto the shaft, and the other is tightened onto the first to lock it in place against the shaft. The set screws are made with a cup at the base that compresses into the shaft, ensuring a secure grip. When re-installing the rotor, please use new set screws. If you do not have spare set screws, the set screws in the rotor need to be reversed, so there is an unused cup being compressed onto the shaft.

If you need to new set screws you, can purchase a PSS O-Ring Kit. This comes with 2 new o-rings, 5 set screws, an allen wrench, Clamp Jackets and Thread Lock.

More Info