PSS Type B Shaft Seal

For 4" to 6-1/2" (100mm to 150mm) shaft diameters

Shop NowProduct Specifications: PSS Type B Seal Dimensions

Downloads: Installation Instructions

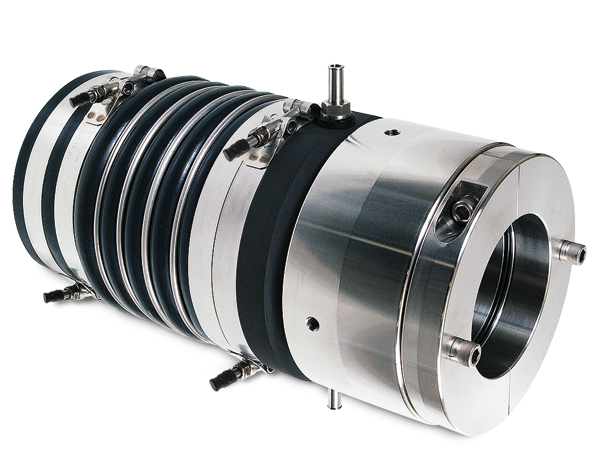

The Type B PSS Shaft Seal is a mechanical face seal. The sealing surface is created between the flat surfaces of the rotating stainless-steel rotor and the stationary carbon flange. The stationary carbon flange is attached to the front side of the bellows with hose clamps, and the back end of the bellows fits over the Stern tube and is secured with hose clamps. The stainless-steel rotor is fitted on the shaft in front of the carbon flange. The stainless-steel rotor compresses the bellows before the rotor is secured to the shaft with set screws. This compression (pre-load) maintains constant contact between the two flat faces of the stainless-steel rotor and carbon flange, allowing the PSS to compensate for the variable fore and aft movement due to propeller thrust. In addition, the carbon flange is over-bored to the shaft diameter allowing it to “float” around the shaft and thus compensate for most misalignment and vibration problems. The stainless-steel rotor is sealed to the shaft by two O-rings recessed into the collar's bore. These O-rings rotate with the shaft and stainless-steel rotor and do not experience wear during operation.

Temperature Limits: -13°F to 425°F (-25°C to 220°C)

Pressure Limits: 50 PSI (3.5 BAR)

Shaft RPM Limits: 7,000 RPM

Carbon Graphite: Lapped to 4 HLB (0.000044" tolerance)

316SS / Nitronic 50: Faced to 9-12 Ra

Bellows Material: Mandrel formed silicone / fabric

Components

Rotor

The rotor on the Type B seal is manufactured out of Nitronic 50 stainless alloy machined to a 9Ra finish on precision CNC lathes. It is secured on the shaft with a large locking collar placed in front of the rotor. This collar (clamp) has a dual purpose: It secures the rotor on the shaft and is used as a tool during installation. As on all the PSS seal families, the carbon stator further polishes the rotor during the initial hours of operations. The Nitronic 50 material is a very high grade of stainless steel, which is almost totally corrosion-resistant.

Carbon Stator

Carbon-graphite is a versatile mechanical seal face material when used with mating rings of a harder material. The PSS carbon has superior wear characteristics and broad chemical resistance.

The high density, resin impregnated carbon stator is manufactured from an advanced composite that is first mixed and molded and then formed under pressure. The blank parts are then baked, machined, and lapped to a measured flatness of 4 helium light bands (measured at 0.000044" of variation over its entire lapped surface). The grade of carbon composite used in the PSS Shaft Seal has a maximum operating temperature of 500°F (+260°C) and cannot melt if the seal runs dry for a short period of time, unlike a lip seal or a plastic face seal. In addition, the high density of the carbon greatly increases longevity and wear resistance. Several commercial vessels have recorded over 40,000 (over 4-1/2 years of continuous operation) engine hours on the same original components.

The PSS Type B carbon stator has dual water injection ports for a positive water supply to be plumbed in.

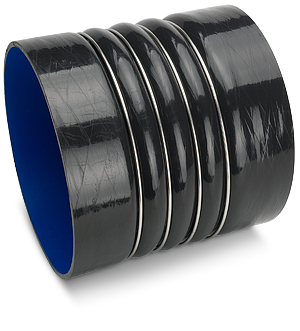

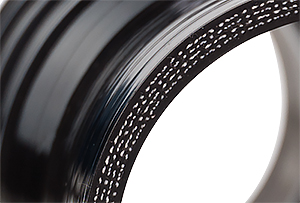

Bellows

The bellows on both the PRO and Type B PSS seal are constructed out of high temp silicone laminated with either 4 or 5 plies of polyester fabric (aramid in larger sizes) and covered with a layer of fluorosilicone. In addition, both ends of the bellows are sealed so no water can get in the polyester/Aramid fabric. The 4 or 5 fabric inlay provides excellent strength to abrasion and resistance to pressure without loading the silicone. On the larger models, the strength is greatly increased by using stainless steel hoops laid into the convolutions of the bellows.

Bellows Rings

The PSS Type B Shaft Seal uses metal rings around the bellows for added strength due to the high pressures that the seal may encounter.

Added Strength

The bellows is reinforced with multiple plies of aramid fabric.

Hose Barb

For high-speed vessels (12+ knots), a positive water supply is required to be plumbed to the PSS Shaft Seal for lubricating and cooling the seal faces. Please review the PSS Shaft Seal Installation Instructions for more information on pickup points for water supply. In most cases, a slow-speed boat (less than 12 knots) that does not have a bearing the shaft log does not require positive water feed and can be vented. Ideally, the vent line will be run at least 2-3 feet above the waterline and as close to the centerline as possible. This will ensure the vent hose is never below the water line, even with significant heeling. Again, PSS Shaft Seal Installation Instructions have more details on venting the seal.

How Does It Work?

1

This clamp assembly maintains the PSS Type B preload / compression without the need for set screws.

2

A seal is created between the two flat surfaces of the carbon stator and the stainless steel rotor.

3

Water is fed into the PSS Shaft Seal for cooling/lubricating the seal faces on high speed vessels.

4

The stationary carbon stator is attached to the nitrile bellows, which is attached to the stern tube (shaft log)

5

Stainless steel rings are fit to the bellows for increased strength, support and durability.

6

Hose clamps secure the PSS Type B Shaft Seal to the stern tube and onto the carbon stator.

7

Hose clamp tail protection, Clamp Jackets.

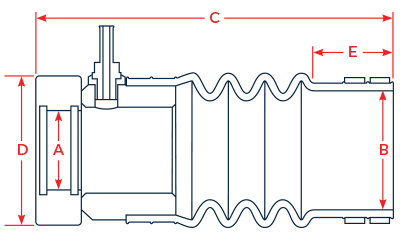

Dimensions

| Part # | Shaft Dia. (A) | Stern Tube Dia. (B) | Uncompressed Length (C) | Approx. Compression | Rotor Diameter (D) | Stern Cuff Length (E) |

|---|---|---|---|---|---|---|

| 02-400-512 | 4" | 5-1/2" to 5-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-534 | 4" | 5-3/4" to 5-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-600 | 4" | 6" to 6-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-614 | 4" | 6-1/4" to 6-3/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-612 | 4" | 6-1/2" to 6-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-634 | 4" | 6-3/4" to 6-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-400-700 | 4" | 7" to 7-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-512 | 4-1/4" | 5-1/2" to 5-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-534 | 4-1/4" | 5-3/4" to 5-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-600 | 4-1/4" | 6" to 6-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-614 | 4-1/4" | 6-1/4" to 6-3/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-612 | 4-1/4" | 6-1/2" to 6-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-634 | 4-1/4" | 6-3/4" to 6-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-414-700 | 4-1/4" | 7" to 7-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-412-512 | 4-1/2" | 5-1/2" to 5-5/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-534 | 4-1/2" | 5-3/4" to 5-7/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-600 | 4-1/2" | 6" to 6-1/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-614 | 4-1/2" | 6-1/4" to 6-3/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-612 | 4-1/2" | 6-1/2" to 6-5/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-634 | 4-1/2" | 6-3/4" to 6-7/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-412-700 | 4-1/2" | 7" to 7-1/8" | 13.189" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-612 | 4-3/4" | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-634 | 4-3/4" | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-700 | 4-3/4" | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-714 | 4-3/4" | 7-1/4" to 7-3/8" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-712 | 4-3/4" | 7-1/2" to 7-5/8" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-734 | 4-3/4" | 7-3/4" to 7-7/8" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-800 | 4-3/4" | 8" to 8-1/8" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-434-858 | 4-3/4" | 8-5/8" to 8-3/4" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-600 | 5" | 6" to 6-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-612 | 5" | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-634 | 5" | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-700 | 5" | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-714 | 5" | 7-1/4" to 7-3/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-712 | 5" | 7-1/2" to 7-5/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-734 | 5" | 7-3/4" to 7-7/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-800 | 5" | 8" to 8-1/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-500-858 | 5" | 8-5/8" to 8-3/4" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-612 | 5-1/2" | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-634 | 5-1/2" | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-700 | 5-1/2" | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-714 | 5-1/2" | 7-1/4" to 7-3/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-712 | 5-1/2" | 7-1/2" to 7-5/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-734 | 5-1/2" | 7-3/4" to 7-7/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-800 | 5-1/2" | 8" to 8-1/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-512-858 | 5-1/2" | 8-5/8" to 8-3/4" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-600-612 | 6" | 6-1/2" to 6-5/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-634 | 6" | 6-3/4" to 6-7/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-700 | 6" | 7" to 7-1/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-714 | 6" | 7-1/4" to 7-3/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-712 | 6" | 7-1/2" to 7-5/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-734 | 6" | 7-3/4" to 7-7/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-800 | 6" | 8" to 8-1/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-600-858 | 6" | 8-5/8" to 8-3/4" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-700 | 6-1/2" | 7" to 7-1/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-714 | 6-1/2" | 7-1/4" to 7-3/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-712 | 6-1/2" | 7-1/2" to 7-5/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-734 | 6-1/2" | 7-3/4" to 7-7/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-800 | 6-1/2" | 8" to 8-1/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-612-858 | 6-1/2" | 8-5/8" to 8-3/4" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| Part # | Shaft Dia. (A) | Stern Tube Dia. (B) | Approx. Length (C) | Approx. Compression | Rotor Diameter (D) | Stern Cuff Length (E) |

|---|---|---|---|---|---|---|

| 02-100M-512 | 100mm | 5-1/2" to 5-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-534 | 100mm | 5-3/4" to 5-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-600 | 100mm | 6" to 6-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-614 | 100mm | 6-1/4" to 6-3/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-612 | 100mm | 6-1/2" to 6-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-634 | 100mm | 6-3/4" to 6-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-100M-700 | 100mm | 7" to 7-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-512 | 110mm | 5-1/2" to 5-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-534 | 110mm | 5-3/4" to 5-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-600 | 110mm | 6" to 6-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-614 | 110mm | 6-1/4" to 6-3/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-612 | 110mm | 6-1/2" to 6-5/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-634 | 110mm | 6-3/4" to 6-7/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-110M-700 | 110mm | 7" to 7-1/8" | 13.189" | 1" to 1-1/4" | 7" | 2.5" |

| 02-115M-512 | 115mm | 5-1/2" to 5-5/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-534 | 115mm | 5-3/4" to 5-7/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-600 | 115mm | 6" to 6-1/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-614 | 115mm | 6-1/4" to 6-3/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-612 | 115mm | 6-1/2" to 6-5/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-634 | 115mm | 6-3/4" to 6-7/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-115M-700 | 115mm | 7" to 7-2/8" | 13.314" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-612 | 120mm | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-634 | 120mm | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-700 | 120mm | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-714 | 120mm | 7-1/4" to 7-3/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-712 | 120mm | 7-1/2" to 7-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-734 | 120mm | 7-3/4" to 7-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-800 | 120mm | 8" to 8-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-120M-858 | 120mm | 8-5/8" to 8-3/4" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-612 | 130mm | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-634 | 130mm | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-700 | 130mm | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-714 | 130mm | 7-1/4" to 7-3/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-712 | 130mm | 7-1/2" to 7-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-734 | 130mm | 7-3/4" to 7-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-800 | 130mm | 8" to 8-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-130M-858 | 130mm | 8-5/8" to 8-3/4" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-612 | 140mm | 6-1/2" to 6-5/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-634 | 140mm | 6-3/4" to 6-7/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-700 | 140mm | 7" to 7-1/8" | 13.742" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-714 | 140mm | 7-1/4" to 7-3/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-712 | 140mm | 7-1/2" to 7-5/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-734 | 140mm | 7-3/4" to 7-7/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-800 | 140mm | 8" to 8-1/8" | 13.42" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-140M-858 | 140mm | 8-5/8" to 8-3/4" | 13.671" | 1" to 1-1/4" | 7.875" | 2.5" |

| 02-150M-612 | 150mm | 6-1/2" to 6-5/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-634 | 150mm | 6-3/4" to 6-7/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-700 | 150mm | 7" to 7-1/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-714 | 150mm | 7-1/4" to 7-3/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-712 | 150mm | 7-1/2" to 7-5/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-734 | 150mm | 7-3/4" to 7-7/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-800 | 150mm | 8" to 8-1/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-150M-858 | 150mm | 8-5/8" to 8-3/4" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-700 | 165mm | 7" to 7-1/8" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-714 | 165mm | 7-1/4" to 7-3/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-712 | 150mm | 7-1/2" to 7-5/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-734 | 150mm | 7-3/4" to 7-7/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-800 | 150mm | 8" to 8-1/8" | 13.9195" | 1" to 1-1/4" | 8.875" | 2.5" |

| 02-165M-858 | 150mm | 8-5/8" to 8-3/4" | 14.2415" | 1" to 1-1/4" | 8.875" | 2.5" |

Tips

Here are some helpful tips to make sure you get the most out of your PSS Shaft Seal.

For more helpful tips, please visit our FAQ page.

PSS Maintenance Kit

To ensure longevity and proper function of the PSS Shaft Seal, PYI provides a PSS Maintenance Kit to follow the PYI's recommended maintenance schedule. As with any rubber or silicone hose below the waterline, the PSS bellows must be inspected regularly for any sign of wear, aging, or chemical deterioration. PYI recommends that the bellows be replaced once every 6 years. During the bellows replacement, it is also recommended that the o-rings & set screws in the stainless steel rotor be replaced and the hose clamps. PYI includes all of the necessary replacement parts in the PSS Maintenance Kit.

More Info

Set Screws

Please be sure never to use the same set screw on the shaft twice. There are two set screws in each of the two holes in the stainless steel rotor. One is tightened onto the shaft, and the other is tightened onto the first to lock it in place against the shaft. The set screws are made with a cup at the base that compresses into the shaft, ensuring a secure grip. When re-installing the rotor, please use new set screws. If you do not have spare set screws, the set screws in the rotor need to be reversed, so there is an unused cup being compressed onto the shaft.

If you need to new set screws, you can purchase a PSS O-Ring Kit. This comes with 2 new o-rings, 5 set screws, an allen wrench, Clamp Jackets and Thread Lock.

More Info