PSS Shaft Seal FAQ's

Q: What general maintenance should I be considering for a PSS Shaft Seal that is working perfectly well with no apparent issues?

A: PYI recommends that the bellows be replaced once every 6 years on our PSS Type A seals and every 8 to 10 years on our PSS PRO and Type B Seals. During bellows replacement, it is also recommended that the o-rings and set screws in the stainless steel rotor be replaced and the hose clamps. Under most circumstances, the carbon stator and the stainless steel rotor will not need to be replaced.

Q: Can I re-use my set screws when making an adjustment or removing the PSS Shaft Seal?

A: No. The set screws provided with the PSS Shaft Seal are cup-point set screws, which compress onto the shaft when tightened. Any re-use of the set screws will not allow the cup point to lock onto the shaft properly. The PSS Maintenance Kit comes with five new set screws included.

Q: I’m hearing a high pitched "squealing" sound that seem to be coming from the shaft seal, what should I do?

A: The first step is to determine with a high degree of certainty that the sound is coming from the shaft seal. If so, this is most likely the result of the shaft seal running dry, and you will want to correct the plumbing to the seal. Fortunately, the PSS Shaft Seal uses high-quality carbon and stainless steel sealing components that will not melt due to water loss, as you see with many other available sealing options.

Q: Does the PSS Shaft Seal have a "break-in" period?

A: On average, the PSS Shaft Seal requires approximately one hour of break-in time, which allows the carbon flange to polish the mating face of the stainless steel rotor. You may experience a very fine mist during the break-in period, sometimes associated with black dust coming from the PSS Shaft Seal. Under normal conditions, this will stop after an average of one hour of running time.

Q: It appears my shaft seal is leaking at rest, what can I do?

A: If the PSS Shaft Seal is leaking at rest, some foreign material is likely on the seal's face between the stainless steel rotor and carbon flange. To clean this material from the seal, carefully insert a clean rag between the sealing faces and work around the seal. A more vigorous cleaning can be performed using a 600 grit wet/dry sandpaper folded in half to have grit on both sides. As you do this, the incoming water will flush the sealing faces, and the leak should stop once the rag is removed and the sealing faces are back in contact.

Q: My seal is beyond the one hour break in period, does not leak at rest, but continues to mist during operation?

A: In most cases, a PSS Shaft Seal that does not leak at rest but only underway and/or at high RPMs is due to a lack of compression. Please note that the installation instructions' compression guide is average figures and is provided as a guide. Exact compression amounts can vary from boat to boat. If the seal continues to spray underway following the break-in period, you will want to verify that the seal has been properly compressed. If it appears that additional compression is needed, add compression in 1/8" to 1/4" increments until the spray or mist stops.

Q: I have a slow speed boat that will never exceed 12 knots under power, do I need positive water feed to my PSS Shaft Seal?

A: In most cases, a slow-speed boat that does not have a bearing, the PSS Shaft Seal does not require positive water feed and can be "vented." Ideally, the vent line will be run at least 2-3 feet above the water line and is close to the centerline as possible to ensure the vent hose is never below the water line, even if the boat heels. Review the PSS Shaft Seal Installation Instructions for more details on venting the seal.

Q: I have a high speed boat that will exceed 12 knots under power, do I need positive water feed to my PSS Shaft Seal?

A: Yes, for high-speed vessels, it is required that a positive water supply be plumbed to the PSS Shaft Seal for lubricating and cooling the seal faces. There are many water supply sources; review the PSS Shaft Seal Installation Instructions for more information and note all plumbing must follow the standards and practices of proper boat plumbing.

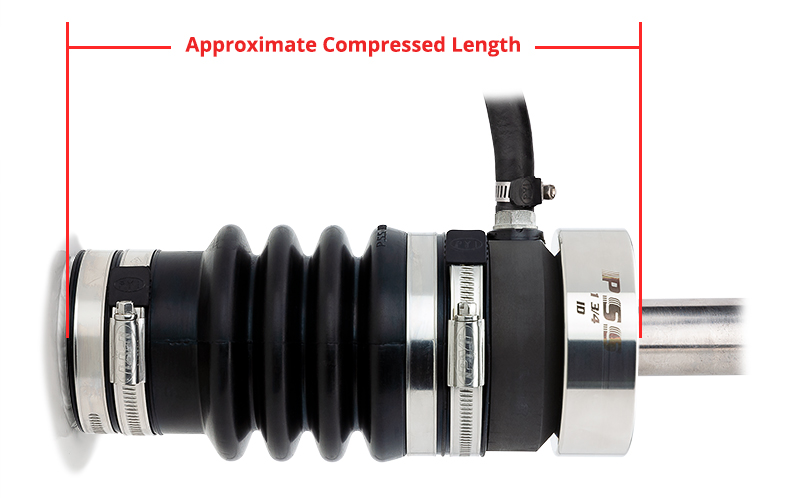

Q: What should the compression be for my PSS Shaft Seal?

A: The chart below lists the overall compressed length of the PSS Type A and Type B Shaft Seals. For PSS PRO Shaft Seal compressed lengths visit the PSS PRO Seal page.

| Shaft Ø | Stern Tube Ø | Approx. Compressed Length |

|---|---|---|

| 3/4", 7/8", 1", 1-1/8" | 1-1/4", 1-1/2", 1-3/4", 2", 2-1/4" | 6.00" - 6.125" |

| 3/4", 7/8", 1", 1-1/8" | 2-1/2" | 6.625" |

| 1-1/4", 1-3/8" | 1-3/4", 2", 2-1/4", 2-1/2" | 6.625" - 6.75" |

| 1-1/4", 1-3/8" | 2-3/4", 3", 3-1/4", 3-1/2" | 8.125" - 8.313" |

| 1-1/2", 9/16", 1-3/4", 2" | 2", 2-1/4", 2-1/2", 2-3/4", 3", 3-1/4", 3-1/2" | 8.00" - 8.218" |

| 1-1/2", 9/16", 1-3/4", 2" | 3-3/4", 4" | 8.405" |

| 2-1/4", 2-1/2" | 3-1/4", 3-1/2", 3-3/4", 4" | 8.625" |

| 2-1/4", 2-1/2" | 4-1/4", 4-1/2", 4-3/4", 5" | 9.25" |

| 2-3/4", 3" | 4-1/4", 4-1/2", 4-3/4", 5" | 9.125" - 9.313" |

| 2-3/4", 3" | 5-1/4", 5-1/2", 5-3/4", 6" | 9.25" - 9.438" |

| 3-1/4", 3-1/2", 3-5/8", 3-3/4" | 4-1/2", 4-3/4", 5", 5-1/4", 5-1/2", 5-3/4", 6" | 9.675" - 9.863" |

| 4", 4-1/4" | 5-1/2", 5-3/4", 6", 6-1/4", 6-1/2", 6-3/4", 7" | 12.189" |

| 4-1/2" | 5-1/2", 5-3/4", 6", 6-1/4", 6-1/2", 6-3/4", 7" | 12.189" |

| 4-3/4", 5", 5-1/2" | 6-1/2", 6-3/4", 7", 7-1/4", 7-1/2", 7-3/4", 8", 8-5/8" | 12.420" - 12.742" |

| 6" | 6-1/2", 6-3/4", 7", 7-1/4", 7-1/2", 7-3/4", 8", 8-5/8" | 12.920" - 13.250" |

| Shaft Ø | Stern Tube Ø | Approx. Compressed Length |

|---|---|---|

| 20mm, 22mm, 25mm, 28mm, 30mm | 30mm, 40mm, 45mm, 50mm, 60mm | 152mm - 156mm |

| 20mm, 22mm, 25mm, 28mm, 30mm | 65mm | 168mm |

| 32mm, 35mm | 45mm, 50mm, 60mm, 65mm | 168mm - 172mm |

| 38mm, 40mm, 45mm, 50mm, 55mm | 50mm, 60mm, 65mm, 70mm, 75mm, 80mm, 85mm, 90mm | 203mm - 209mm |

| 38mm, 40mm, 45mm, 50mm, 55mm | 95mm, 100mm | 213mm |

| 60mm, 65mm | 85mm, 90mm, 95mm, 100mm | 219mm - 224mm |

| 60mm, 65mm | 110mm, 115mm, 120mm, 125mm | 235mm |

| 70mm, 75mm, 80mm | 100mm, 110mm, 115mm, 120mm, 125mm | 231mm - 237mm |

| 70mm, 75mm, 80mm | 135mm, 140mm, 145mm, 150mm | 235mm - 240mm |

| 85mm, 90mm, 95mm | 115mm, 120mm, 125mm, 130mm, 135mm, 140mm, 145mm, 150mm | 245mm - 250mm |

| 100mm, 105mm, 110mm | 140mm, 145mm, 150mm, 160mm, 165mm, 170mm, 180mm | 310mm |

| 115mm | 140mm, 145mm, 150mm, 160mm, 165mm, 170mm, 180mm | 310mm |

| 120mm, 130mm, 140mm | 165mm, 170mm, 180mm, 185mm, 190mm, 195mm, 205mm, 220mm | 315mm - 324mm |

| 150mm | 165mm, 170mm, 180mm, 185mm, 190mm, 195mm, 205mm, 220mm | 328mm - 337mm |

Q: What is shaft / stern tube Targetting? And What are the issues?

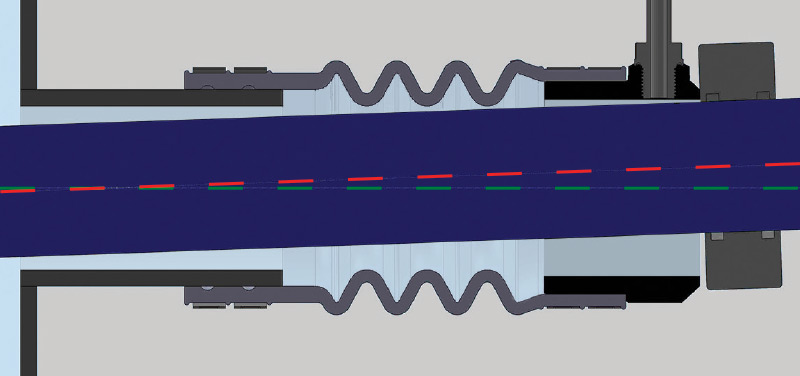

A: The carbon flange is over-bored to compensate for most misalignment issues. However, there are several boat models that have "shaft and stern tube targeting" issues beyond what the carbon flange "standard bore" can make up for. Shaft targeting (often confused with alignment) is a factor of the shaft and stern tube orientation, where the shaft is not centered in the stern tube where it enters and exits the boat. Or the stern tube is not running parallel to the shaft. The result (as depicted to the right) is a shaft that passes through the seal at an angle, and the outcome is often a leaking seal, notably at high rpm due to the shaft contact inside the carbon flange disrupting the mechanical seal.

Most common boats we see targeting issues are:

- Bayliner

- Tiara

- Meridian

- Sea Ray

Corrective Action

Generally, we look at (2) countermeasures and considerations for installations with targeting issues:

- Adjust or angle the bellows component on the stern tube to allow the shaft to pass through the center of the carbon component.

- Install the PSS seal using an "over bored" carbon component to increase the margin of error of the shaft contacting the component internally.

Q: Can I install the PSS Shaft Seal on a bronze propeller shaft?

A: Yes, you can install a PSS Shaft Seal on a bronze propeller shaft, and it should not pose a significant concern regarding dissimilar metals.